Steel minimill company supporting a recycling-oriented society

Steel producers are roughly divided into two types: integrated steel producers and steel minimill companies.

While integrated steel producers produce steel using iron ore as the main material, steel minimill companies, like us, produce steel stock using steel scrap, steel whose role as products is finished, as the main material, to respond to social demand as companies that support a resource recycling-based society.

Steel minimill companies have extremely low CO2 emissions of about 1/3 to 1/4 compared to integrated steel producers, and have realized an earth-friendly production method that has less impact on the environment.

Furthermore, the Kyoei Steel Group has succeeded in completely detoxicating and recycling waste by using arc heat at several thousand degrees, which is generated when steel scrap is melted. In the material recycling business, in which such technology is utilized, we are also contributing to recycling resources and conserving the environment in Japan.

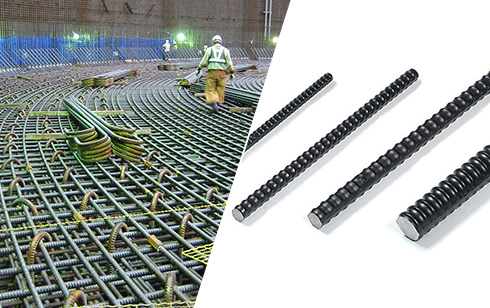

Commanding the largest domestic market share of

concrete reinforcing bar

Concrete reinforcing bar (rebar), which is widely used for buildings, condominiums, expressways, etc., is indispensable for our lives and important materials that support social infrastructure. With rebar as the mainstay, the Kyoei Steel Group stably supplies quality products to local customers. We have the largest domestic market share in the production and sale of rebar. In addition to rebar, we offer various types, grades and sizes of steel products, including flat bar and equal angle bar, responding to the diverse needs of our customers.

Operating community-based business in the four major domestic demand areas

Since steel is heavy, the transportation costs are high. For this reason, many steel minimill companies have established a business model of local production for local consumption whereby they recycle steel scrap generated in each region and supply products there.

The Kyoei Steel Group owns plants in all four major areas of demand for concrete reinforcing bar: the Kanto, Chubu, Kansai, Chu-Shikoku and Kyushu regions.

With a production and sales structure that quickly responds to differing market trends in each region, we enjoy superiority in the steel minimill industry.

Pioneer in the material recycling business utilizing electric arc furnaces

Pioneer in the material recycling business utilizing electric arc furnaces

When steel scrap is melted in an electric arc furnace, arc heat of temperatures of 3,000 to 7,000°C is generated.

Our material recycling business started from the idea of effectively utilizing the heat generated in electric arc furnaces to promote environmental conservation and resource recycling.

The Kyoei Steel Group developed a proprietary technology for completely detoxifying and recycling industrial waste and medical waste round 35 years ago.

By appropriately treating ever-increasing waste, we fulfill our responsibilities as a corporate citizen and thereby help realize a sustainable society.

Over 75 years of history supporting the domestic industry

In 1938, Kyoei Forging Shop, the predecessor to Kyoei Steel, was established.

After World War II, the forging shop was closed for some time; however, out of desire to be involved in steelmaking, which was indispensable to the reconstruction of Japan, the founder established Kyoei Iron. After that, the company continued to support the domestic industry.

In 1948, the company was renamed Kyoei Steel.

We have now established ourselves as one of the leading steel minimill companies in Japan after not only having expanded business in Japan, but also having taken up various challenges, including making inroads into the U.S. market for the first time as a steel producer.

Kyoei Steel, which celebrated the 75th anniversary of its founding in 2022, will continue to aim to become a 100-year-old company under its management philosophy, “Spirit of Challenge.”

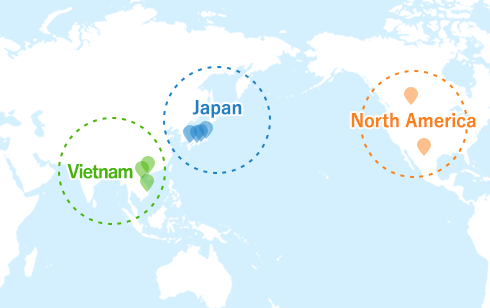

Establishing a global tripolar structure:

Japan, Vietnam and North America

In 1963, Kyoei Steel provided technical guidance and made an investment related to the construction and operation of a rolling mill in Taiwan.

That was the first overseas expansion as Kyoei Steel and a steel minimill company in Japan.

Since then, inheriting the founding spirit of “contributing to building infrastructure across the world through steelmaking,” we have concentrated on expanding our overseas business, including constructing plants and providing technical guidance throughout the world.

Currently, the Kyoei Steel Group operates in Japan, Vietnam, a growing market, and North America, a mature market.

We aim to achieve further growth of the Group by being sure to grasp global steel demand, which continues to expand, and establishing the tripolar global system.

Inheriting our predecessors’ spirit and fostering human resources for the next generation

Since our founding, we have overcome a multitude of difficulties and have been developing Japanese steelmaking across the world.

What has made this possible is Kyoei’s DNA of “Spirit of Challenge,” which encourages its employees to open the way without fear of difficulties.

It is the key to corporate growth and also our mission to pass our continuously inherited DNA on to the next generation.

By providing various opportunities for education and self-fulfillment, we are putting our energies into fostering independent human resources that will create the next generation.

Contributing to realization of a sustainable society, continuing to take on challenges toward the future

We will work on coexistence with the global environment, nature and communities by further developing technologies for recycling steel resources that we have established.

Aiming to become a 100-year-old company, we will continue to take on challenges toward the future while asking ourselves what we can do as a steel minimill company.

Please click the following links for details